Neon Lamps: Application & Technical Notes

Below is technical and application information on ILT's Neon Lamps. Many of our lamps can be purchased right from our e-store. To speak with one of our lamp experts, inquire about a customized lamp, or to ask about a sample, contact us using the form below.

Browse Lamps

Speak With An Expert

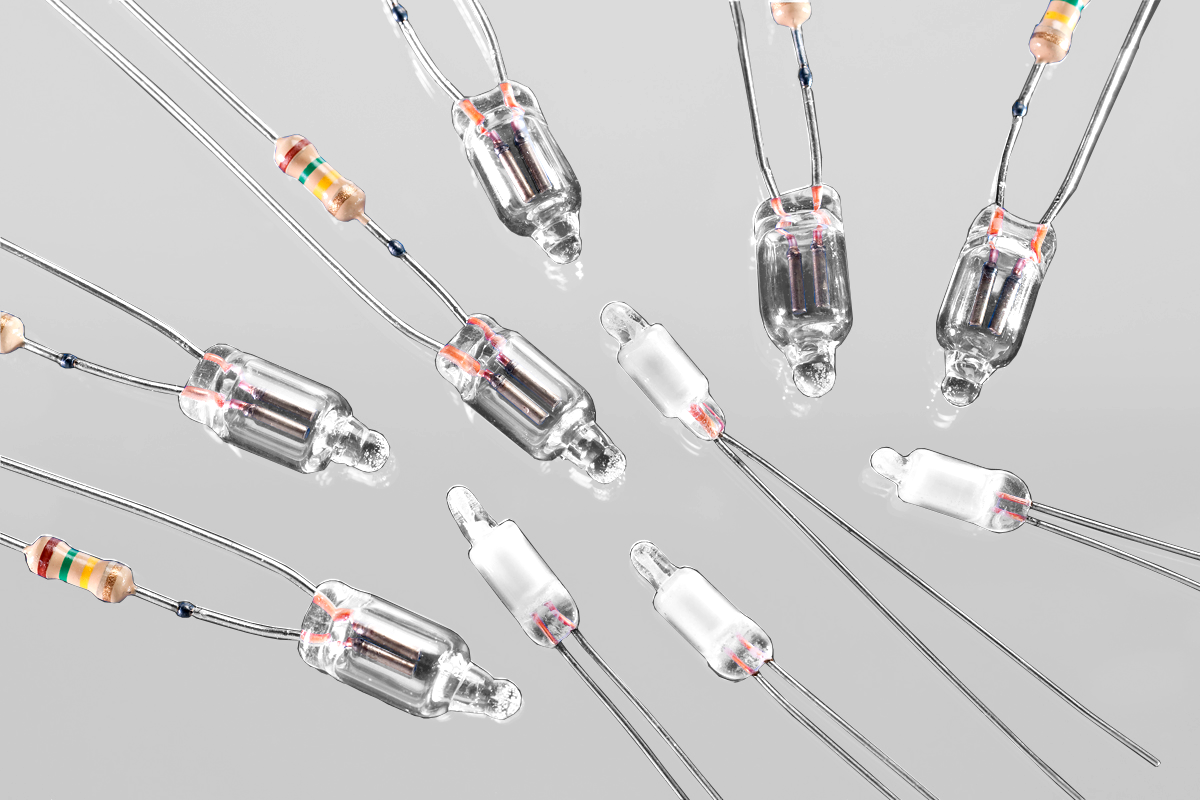

Neon lamps are recommended for 110 volt AC, 220 volt AC, and DC applications in excess of 90 volts. The lamps are available in miniature and sub-miniature sizes.

Neon lamps are recommended for 110 volt AC, 220 volt AC, and DC applications in excess of 90 volts. The lamps are available in miniature and sub-miniature sizes.

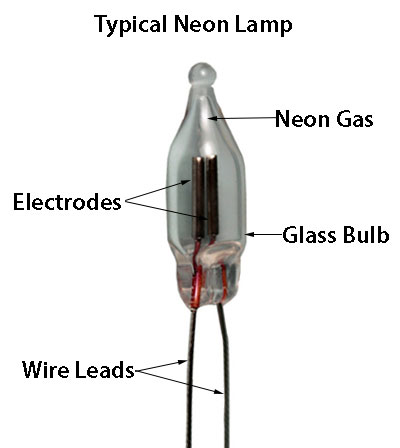

A neon lamp is constructed by mounting two electrodes within a small glass envelope. Two wire leads made of tin plated Dumet metal are brought out of the lamp to make electrical connections to the electrodes. Standard brightness lamps are filled with a neon/argon gas mixture, and high brightness lamps are filled with pure neon gas. When a starting voltage (usually 55-110 volts AC, or 90-140 volts DC) is applied, the gas ionizes and starts to glow permitting a very small current to travel from one electrode to the other. Once ionized, a lower voltage will maintain the operation of the lamp. The maintaining voltage is usually 10-20 volts below the starting voltage, depending on the lamp and the operating current. For lamps operating on AC voltages of 60 Hz or higher frequency, the light output will appear to the eye as continuous.

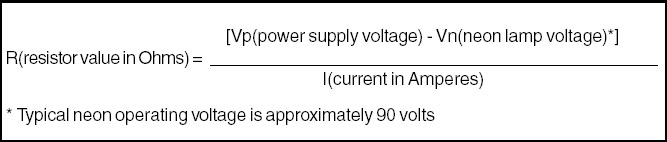

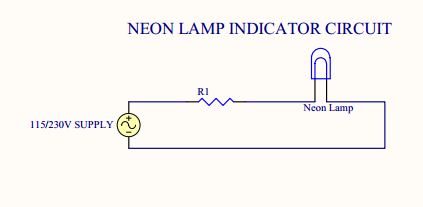

When the gas ionizes it becomes a conductor, and an external series resistor is required to limit the current. To calculate the value of the series resistor, subtract the maintaining voltage from the supply voltage to obtain the voltage across the resistor, then use Ohm's Law and desired current level to determine resistance value.

Typical resistance values range from 10 KiloOhms to 220 KiloOhms. The power dissipation of the required resistor is small, usually less than 1/4 watt, but should be checked for high voltage applications. Typical current for neon lamps is between 0.5 and 3.0 mA. Power dissipation in the resistor can be calculated by the following formula:

P(power in watts) = I(current in Amperes) x I(current in Amperes) x R(resistor in Ohms)

Neon lamps are very rugged and not affected by vibration, mechanical shock, or frequent ON/OFF operation. Neon lamps may be operated over a wide temperature range from -40 to +150 degrees C, and are not damaged by voltage transients of high voltage static discharges.

Neon lamps have a special operating characteristic that also allow them to be used as moderately stable high voltage reference voltage sources. When driven with DC voltage at their design current the voltage across the lamp is stable at a value near 90 volts.

Neon lamps gradually decline in light output as electrodes evaporate and condense on the inside of the glass envelope. This situation is gradual with failure defined as a 50% decrease from the original brightness. As neon lamps age, the firing voltages slowly increase until reaching the value of the supply voltage. At this point the lamp flickers and becomes erratic, indicating the end of useful lifetime.

Life expectancy of a neon lamp increases considerably as operating current is decreased. For high brightness lamps, there is a 4 to 5 power inverse relationship between current and life, whereas for standard brightness types, the lamp life varies inversely as the 3.5 power of the current. With light output exponentially proportional to current, large increases in rated life can be obtained with small reductions in current and only a small reduction in brightness. For neon lamp applications requiring life ratings of more than 50,000 hours the use of a higher value resistor will reduce lamp current and achieve longer life.

The maximum operating temperature for a neon lamp is approximately 150 Deg C. To prevent premature failure it is often best to use in temperatures under 125 or 130 Deg C.

For DC operation, the life of a high brightness lamp is about 50% of a neon lamp operating at the same RMS AC voltage. The life of a standard brightness lamp at DC is about 60% of the life value at AC.

Typical light output color for clear glass neon lamps is in the orange-red range of 600 to 700 nanometers. Other emitted colors as green, yellow and blue are available through secondary emission by coating the inside surface of the envelope with phosphor.

Why Use Neon Lamps as Indicator Lamps

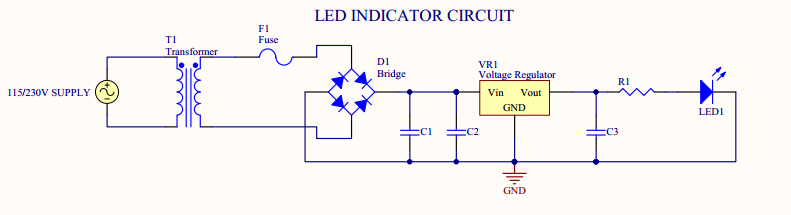

Indicator lamps, also called pilot lights, are used on just about every kind of electrical or electronic equipment imaginable. Most new applications use Light-Emitting Diodes (LEDs), with the exception of AC mains indicators or pilot lights where neon lamps are still popular.

Neon Lamps

- Long life

- Very low current drain

- Resistant to shock and vibration

- Cool operation

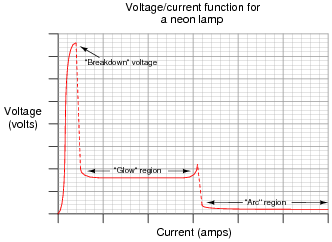

The voltage and current relationship for neon lamps is shown above. There is no current flow until the voltage reaches the striking voltage (first peak). The current will increase (it will depend on the impedance of the circuit) and the voltage will drop to the operating voltage, which is the normal glow range of the lamp. Changes to the current will have little impact until you reach the next point and arc is created producing the abnormal glow region. Neon lamps should be operated in the normal glow (sometimes called the “negative glow”) region.

Simple circuit diagrams below show the difference in complexity between the neon and led indicator lamps.

NEON LAMP INDICATOR vs LED INDICATOR

(In 115/230V Environment)

Gases – neon lamps are filled with inert gases, of which the primary gas is neon. Additional gases, such as helium, argon, and krypton, can be added to change the lamp charactoristics.

Electrodes – nickel is the primary metal for neon lamp eletrodes, which are then coated with materials to lower the breakdown voltage. The length of the electrodes determines the current capacity and the length of the glow.

Temperature – the recommended operating temperature is -50° F to 160° F. The maintaining voltage decreases as the temperature increases.

Neon Lamp Features and Benefits

Neon lamps are typically used in applications that require a wide range of temperatures, brightnesses, and voltages. There are several different colors and brightnesses available.

Neon lamps are very rugged and not affected by vibration, mechanical shock, or frequent ON/OFF operation. Neon lamps may be operated over a wide temperature range from -40 to +150˚C and are not damaged by voltage transients of high voltage static discharges.

Neon lamps have a special operating characteristic that also allow them to be used as moderately stable, high voltage reference voltage sources. When driven with DC voltage at their design current the voltage across the lamp is stable at a value near 90 Volts.

Neon lamps gradually decline in light output as electrodes evaporate and condense on the inside of the glass envelope. This situation is gradual with failure defined as a 50% decrease from the original brightness. As neon lamps age, the firing voltages slowly increase until reaching the value of the supply voltage. At this point the lamp flickers and becomes erratic, indicating the end of useful lifetime.

Life expectancy of a neon lamp increases considerably as operating current is decreased. For high brightness lamps, there is a 4 to 5 power inverse relationship between current and life, whereas for standard brightness types, the lamp life varies inversely as the 3.5 power of the current. With light output exponentially proportional to current, large increases in rated life can be obtained with small reductions in current and only a small reduction in brightness. For neon lamp applications requiring life ratings of more than 50,000 hours the use of a higher value resistor will reduce lamp current and achieve longer life.

For DC operation, the life of a high brightness lamp is about 50% of a neon lamp operating at the same RMS AC voltage. The life of a standard brightness lamp at DC is about 60% of the life value at AC.

Typical light output color for clear glass neon lamps is in the orange-red range of 600 to 700 nano-meters. Other emitted colors such as green, yellow and blue are available through secondary emission by coating the inside surface of the envelope with phosphor.

Neon Terminology

Striking Voltage: The voltage at which the neon lamp ignites is usually between 45 and 65VAC for standard brightness types and between 70 and 95VAC for high brightness types. This is some- times called the breakdown or ignition voltage.

Maintaining Voltage: The voltage across the lamp after it has ignited. This voltage is a function of the lamp current and is usually quoted at the design current. Nominal values are 80V for standard brightness and 75V for high brightness lamps.

Extinction Voltage: The voltage at which the lamp extinguishes if the supply voltage is reduced. It is normally a few Volts below maintaining voltage.

Design Current: The current at which the lamp has been designed to operate. It will be determined by the supply voltage and the value of series resistance. Operation at lower currents will result in the glow discharge becoming unstable (i.e. flickering) and operation at higher currents can severely reduce the useful life of the lamp. It is therefore important to use only the recommended value of series resistance.

Dark Effect: All ILT Neon lamps are subject to a condition called dark effect. Dark affect is defined as a drastic increase in the amount of voltage required to make a lamp glow when the lamp is in a dark environment. Because the lamp is photosensitive, it may require many additional volts to start if no light is present. Neon lamps can also become erratic in total darkness.

To prevent dark affect an external source may be run near the neon lamps or in some cases, custom Neon lamps can be supplied with a radioactive gas, often Krypton 85.