FLEXO-ILT2400

FLEXO-ILT2400

Hand-held UVA / UVC Light Meter For Validating Flexography Processes

Features

- Research Quality at a Hand-held Price

- 8 Decade Dynamic Range of Optical Analysis

- Made in USA

- Meter & Sensors with NIST Traceable ISO/IEC 17025:2017 Accredited Calibration

- Hand-held, Compact, Ergonomic Design

- Brilliant 4.3” Touch Screen Display

- 90° Screen Rotation for Landscape and Portrait Viewing

- ILT’s Accuspan: Auto-ranging with Smart Averaging

- Built-in Rechargeable Battery Lasts Up to 8 Hours

- Backwards Compatible with ILT1700 Sensors

- Measurement Speeds Up to 100 μSeconds

- Custom & OEM Inquiries Welcome

FLEXO-ILT2400 Flexography UVA/UVC Light Meter

The FLEXO-ILT2400 light meter has been specially configured to validate light sources used in Flexography printing and plate making. The FLEXO-ILT2400 is a UVA and UVC light measurement system for verifying light uniformity, irradiance, plate exposure, and dose required to post expose (UV‐A) and detack, or light‐finish (UV‐C) photopolymer plates.

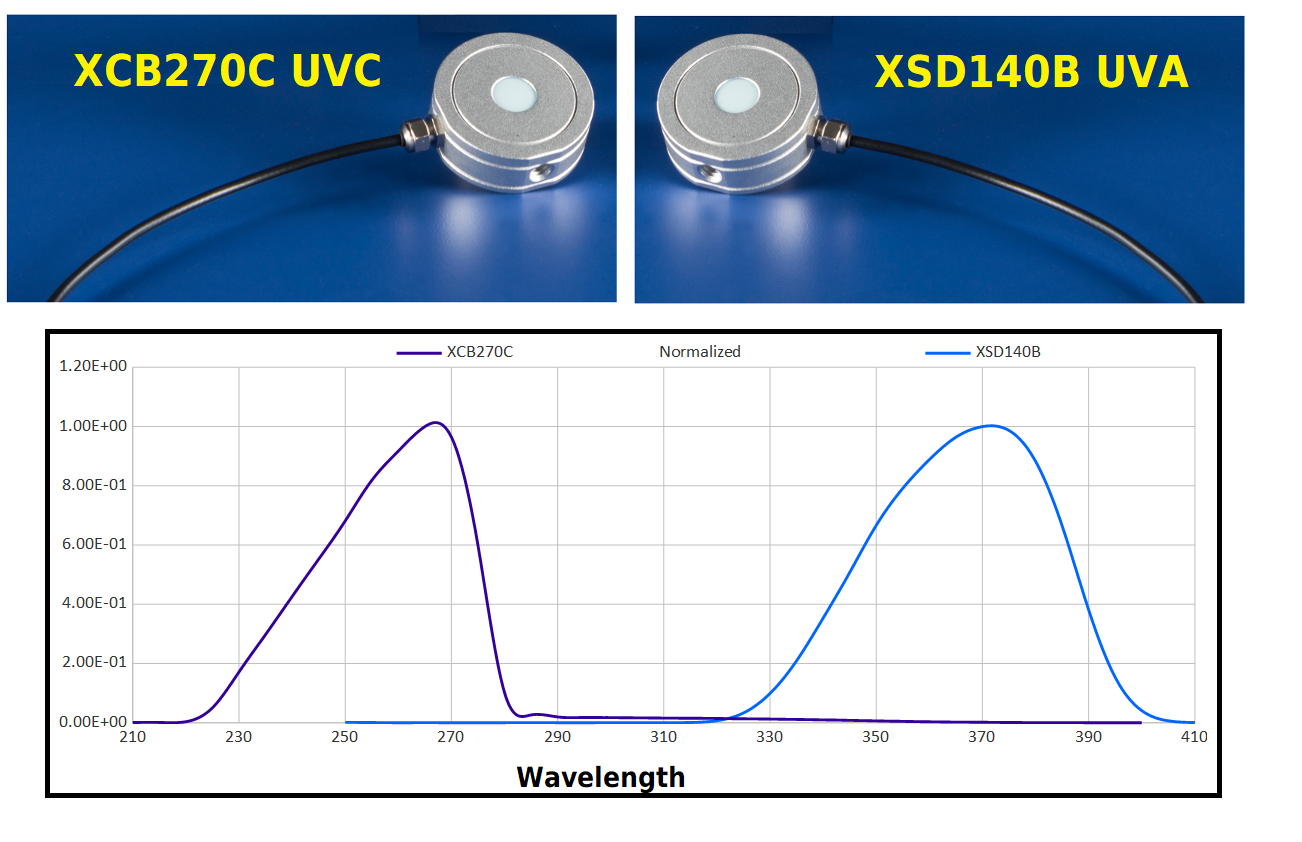

The FLEXO-ILT2400 light meter can be ordered with either or both of the detectors below:

| XSD270C Low profile UVC sensor | XSD140B Low profile UVA sensor |

| Range: 1e-6 – 10 W/cm² | Range: 2e-7 – 1 W/cm² |

| Measures 220-280 nm | Measures 326-401 nm |

| XIR Calibration at 254 nm | PIR Calibration at 365 nm |

| Dimensions: 15 mm x 42 mm with 7 foot cable | Dimensions: 15 mm x 42 mm with 7 foot cable |

About Flexography

Also referred to as "flexo printing", is a printing process produced from a flexible relief plate. Flexo printing can be done on almost any material including plastic, metallic films, cellophane, and paper and is particularly good for food packages because it incorporates food-safe inks.

Ultraviolet light plays a critical role in the flexo printing process. UVA light is used to polymerize the complete height of the polymer. UVA and UVC light is then used for light finishing and detacking of the polymer. In both instances, ensuring the proper dose of light is critical to generating a properly exposed plate.

Utilizing the FLEXO-ILT2400 to validate the UV light sources is a critical step to ensuring quality, repeatable plate making. It can pinpoint problem areas, assist in troubleshooting, and minimize downtime and waste.

Watch our video on the FLEXO-ILT2400 below

See ILT2400 product page for complete meter specifications, documentation, and downloads.