About Lamps for Optical Sorting Applications

Optical sorting is an automated process of sorting products by illuminating and digitally inspecting items. Optical sorters are used in multiple industries including the food and agricultural industry, for processing harvested foods such as potatoes and other vegetables, fruits, berries, and nuts. The technology is also used in waste recycling, pharmaceutical and nutraceutical manufacturing, mining, tobacco processing, and more.

Optical sorters recognize an object's shape, color, structural properties and/or chemical composition. The sorter compares objects to the user-defined criteria to identify and remove defective items and foreign materials, as well as to separate products of different grades, sizes or composition.

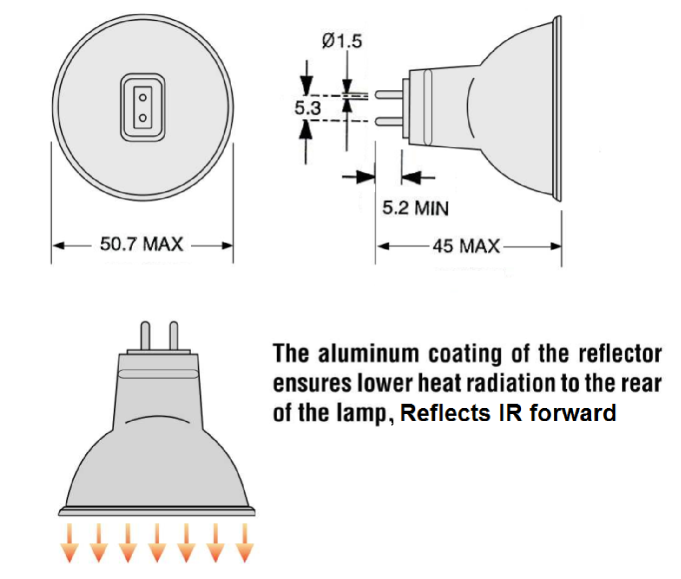

Aluminum MR16 reflector lamps are often the lamp of choice for many optical sorting instruments, such as food processing, recycling, trash sorting, and reverse vending machines.

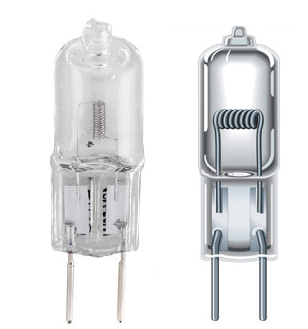

Aluminized MR16 lamps are single-ended quartz halogen filament capsules mounted in a ~ 51 mm diameter reflector that focuses the light into the required location. MR16 Reflectors come in both smooth and faceted surfaces that are coated with a thin layer of Aluminum. Lamps cover in a variety of power levels from 10 Watts up to 350 Watts.

Features of MR16 lamps for optical sorting:

Surface and size

MR stands for multifaceted reflector (often abbreviated MR). The number after the MR is the size of the reflector in eighths of an inch. So an MR16 is 16 eighths of an inch, or 51 mm. Other sizes include MR11 (1-3/8 inch, or 35 mm), and an MR8 (1 inch, or 25 mm) in diameter. Though the definition of MR is multi-faceted, MR16 reflectors actually come in two standard surfaces; both smooth and faceted. Smooth reflectors often create a tighter more precise distribution with maximum throw, whereas the faceted reflectors offer a litter wider dispersion that is more smooth or even in appearance.

Coatings

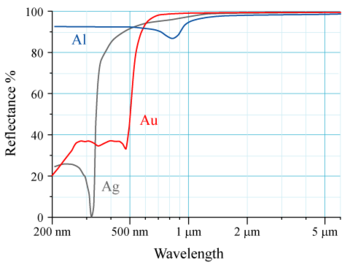

A dichroic coating is a thin, multi-layer dielectric (non-metallic film) that allows infrared radiation (heat) from the halogen bulb to pass through the back side of the reflector and reflects the visible radiation (light) forward.

A metallic coating is typically a thin film of aluminum (Al), gold (Au), or silver (Ag), applied to the glass reflector surface to reflect both infrared and visible radiation forward.

Although aluminum has some reduction in reflectance in the NIR range in the 700-1000 nm as compared to silver and gold, aluminum coatings are often chosen over gold and silver due to significantly lower costs. Additionally, the aluminum won't fade or tarnish over time.

Directionality

Aluminum reflectors not only prevent heat from escaping out the back of the bulb to the inside of the lamp housing where they may heat up and damage components, they also impact the spectrum emitted out the front of the lamp and control how much of the light is directed to a given area.

Parabolic- Collimating reflectors

Parabolic reflectors project the light into a parallel beam or wavefront. These collimating reflectors are designed to produce a small, uniform, spot of light.

Ellipsoidal-Focussing reflectors:

Ellipsoidal reflectors collect the lamp output and focus it forward into an intense pattern at a specified distance. Ellipsoidal reflectors are typically available are all sizes from MR3 - MR16 with a working distance ranging from approximately 5 mm to 200 mm.

Beam angle

The beam angle of a lamp is the angle at which the light is distributed or emitted. Halogen lamps come in a variety of angles from 4 degrees to 60 degrees.

The are often classified by the range of the degree

SP (spot): 4-19 degrees

FL (flood): 20-35 degrees

WFL (wide flood): 36-49 degrees

Filament designs and placement

All reflector lamps incorporate a single-ended lamp, which is mounted in the center of the reflector. Filament configuration is generally determined by the beam characteristics required by the optical system. Though many filament designs are available for use in reflector lamps, the most popular are the C-8, with a vertical filament, and the CC-6 which lies horizontally.

Some precision lamps used in medical instrumentation require the position of the filament in the reflector to be in a very specific location in order to achieve a specific light pattern. This is often done using sensitive measuring systems during assembly. Most general lighting and sorting lamps do not require this level of precision.

Window

Some MR16 lamps have a cover glass on the front end of the reflector. This cover is a safety measure designed to contain any broken fragments in case the lamp shatters when it fails. Windows may be constructed of glass or quartz. Different materials and thicknesses can impact the total light as well as spectrum. Some glasses may also be added to block harmful UV rays.

ILT lamps for optical sorting

Below is a list of lamps that ILT offers for optical sorting applications, most available to purchase right in our on-line store. Use the link HERE to view these lamps in tabular format. Click the TYPE filter to see all aluminum reflector lamps together. ILT can also provide customization to meet your application. To speak with someone about a custom solution, please fill out our contact form HERE.

L2020

L3512

L2012

L3520

L521A

L1090

GTL-OS-54123

L6430

L519-G