Core Competencies - Specialty Light Sources

Customized Light Source Solutions for Specialized Applications

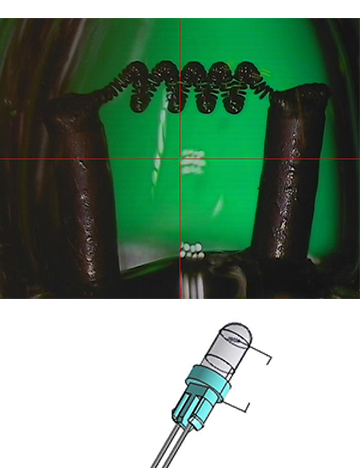

ILT has been delivering both off-the-shelf and customized light sources and reflectors to its customers for over fifty years. Our lamp products cross the entire spectrum of light from ultraviolet to infrared for applications including medical, diagnostic, gas sensing, machine vision, and more. We offer many off-the-shelf lamps that are designed with precision tolerances and beam patterns for many specialized applications. In addition to our off-the-shelf lamps, ILT works with customers of all types and sizes to design and develop precision lamp and reflector technologies to create customized reflectors, reflector coatings, lamp envelopes, filaments, connectors, and more. Our optical engineering team can tackle modeling and design projects from simple to complex. Below are just some of the expertise we offer our customers. To speak with one of our experts on your custom requirements, contact us today.

Our Capabilities

- Technical Consulting

- Engineering & Design

- Manufacturing (ISO 9001:2015)

- Lamp Conditioning and Testing

- OEM Solutions

Technical Consulting

Our team of technical specialists can analyze and improve upon existing designs as well as engineering entirely new solutions. Support is available via text, email, web conference, telephone as well as at our facility.

Design and Engineering

ILT employs a team of optical, mechanical, electrical, quality and manufacturing engineers able to assist you with your technical needs. We also maintain an in-house ISO17025 accredited calibration and light measurement lab. Our technical experts can assist you with:

- Component Selection

- Vendor and Supply Chain Management

- Mold Design

- PCB Design

- Reflector Design

- Reflector and Mold Coatings

- Prototyping

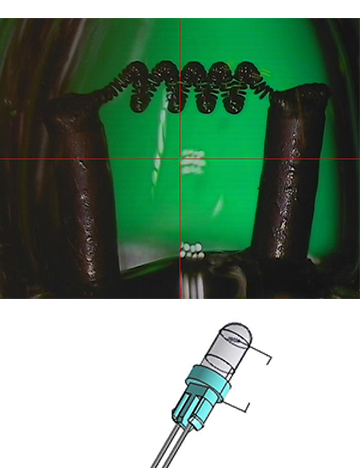

- Custom Lamp Design

- Envelope size

- Filament size and location

- Lamp base (bi-pin, wire lead, threaded, SMT)

- Life hours, current/voltage and output modifications

Manufacturing

ILT manufactures many of its products at its headquarters in Peabody, Massachusetts. ILT manufacturing practices conform to ISO9001:2015 guidelines assuring the highest quality and consistency in our products. ILT's custom lamp

manufacturing includes:

- Epoxy

- Cements

- UV cure adhesives

- Reflector modification (drilling, threading, etc.)

- Target/Focusing

- Customer specified working distance/spot size

- Custom wire

- Soldering

- Crimping

- Extended leads

- Pre-mounted lamps on PCBs or custom holders

Testing, Conditioning and Certification

ILT maintains an in-house testing and certification lab that is NIST traceable and ISO17025 accredited. We offer the following services:

- Lamp Conditioning

- Burn in/Aging

- Pre-selection/Sorting

- Testing

- Lamp testing

- Transmission and optical density testing

- Calibration and Certification for spectral distribution and light output

- View our Calibration Services page

OEM Solutions

ILT can help you design a lighting solution that will meet your unique application requirements and set your product apart from your competitors. We offer a comprehensive array of customizable products and services to meet your development and production needs. If you are spending valuable time and resources designing, building and testing a light source, now is a great time to partner with ILT so you can focus on what you do best -- innovation. Below is just some of the capabilities we offer our customers:

- Co-engineering

- Product customization

- Prototyping

- New product development

- Private label and packaging