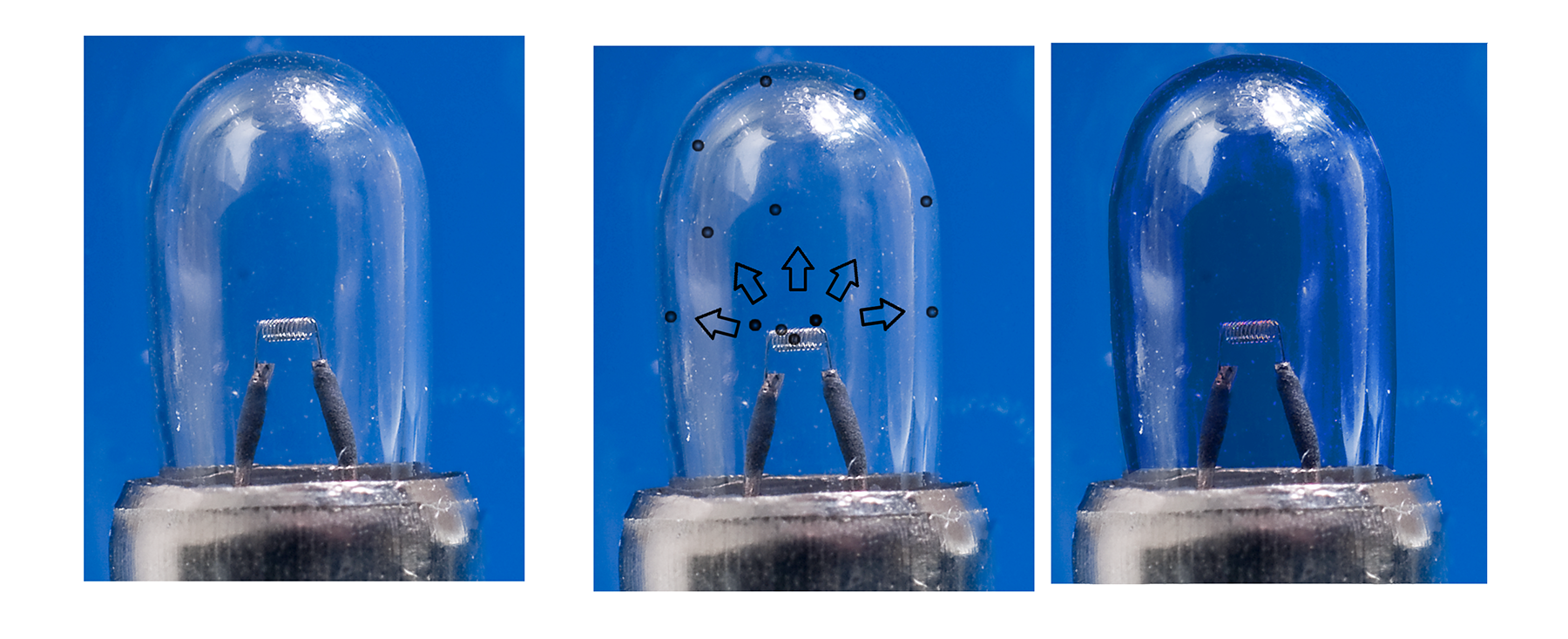

One of the most damaging events to the incandescent lamp is the water cycle. This can occur with even the minute amounts of moisture (water) remaining inside the lamp glass during the production process. When the temperature of the environment exceeds 100 deg C the high temperature breaks the water vapor down into hydrogen and oxygen. The free oxygen then reacts with the hot tungsten filament to produce tungsten oxide.

The tungsten oxide is deposited on the cooler bulb wall and allows the hydrogen, which was freed when the water decomposed, to recombine with the oxygen, producing water again. This will then start the whole process over again.

As this process continues the tungsten deposited on the lamp glass envelop will darken the glass, reducing the output of the lamp and weakening the filament structure as the tungsten from the filament remains in the glass. The water cycle causes rapid darkening of incandescent lamp bulbs, and when enough of the filament has been removed, the filament will break and the lamp will fail, usually in a very short time.

For high temperature lamps, or to learn more about how ILT can provide you a custom solution, please contact us here.